The Relationship Between PCB Trace Width and Current, It's So Useful

The following summarizes eight formulas, tables, and calculation formulas for the relationship between current and trace width. Although they vary somewhat (generally similar),

engineers can consider the size of the PCB board and select an appropriate trace width based on the current in actual PCB board design.

ONE PCB current and trace width

Calculating the current-carrying capacity of a PCB has always lacked authoritative technical methods and formulas, relying instead on the experience of seasoned CAD engineers to make relatively accurate judgments. However, for CAD novices, encountering such a challenge can be daunting.

The PCB's current-carrying capacity depends on the following factors: trace width, trace thickness (copper foil thickness), and allowable temperature rise. It's commonly understood that wider PCB traces can carry more current. Assuming under the same conditions, a 10-mil trace can handle 1A, does that mean a 50-mil trace can handle 5A? The answer is naturally negative. Please refer to the data provided by internationally recognized institutions:

The unit for trace width is: Inch (1 inch = 2.54 cm = 25.4 mm)

TWO Relationship between Copper Thickness, Trace Width, and Current in PCB Design

Before understanding the relationship between copper thickness, trace width, and current in PCB design, let us first understand the conversion between units of PCB copper thickness: ounces, inches, and millimeters.

"In many data sheets, the PCB copper thickness is often measured in ounces, and its conversion to inches and millimeters is as follows:

1 ounce = 0.0014 inches = 0.0356 millimeters (mm)

2 ounces = 0.0028 inches = 0.0712 millimeters (mm)

Ounces are a unit of weight, and the reason they can be converted to millimeters is because PCB copper thickness is measured in 'ounces per square inch'!"

You can also use empirical formulas for calculation: 0.15 × Line Width (W) = A. The data provided above represents the current-carrying capacity of the traces at a temperature of 25°C.

Wire impedance: 0.0005 × L/W (Wire Length/Wire Width).

In addition, the current-carrying capacity of the wire is directly related to the number of pads and vias:

The current-carrying capacity of the wire is directly related to the number of pads and vias (currently, there is no formula found for the influence of pad and via diameter per square millimeter on the current-carrying capacity of the wire, interested individuals can search for it themselves, I am not too clear personally, not mentioned here). Here are some main factors affecting the current-carrying capacity of the wire.

1.The values listed in the table data are the maximum current-carrying values that can be sustained at normal temperature (25°C). Therefore, in actual design, various factors such as environment, manufacturing process, board material process, and board material quality should be considered. Therefore, the provided table serves only as a reference value.

2.In actual design, each wire will also be affected by the pads and vias. For example, segments with more pads on the wire, after soldering, the current-carrying capacity of that segment of the wire will be greatly increased. Many people may have seen some wire segments burned in boards with high currents. The reason is simple: after soldering, the segment between the pads increases its current-carrying capacity due to the components' pins and solder, and the maximum current-carrying capacity between the pads is also the maximum allowed current-carrying capacity of the wire width. Therefore, during the circuit's instantaneous fluctuation, it is easy to burn the wire segment between the pads. Solution: Increase the wire width. If the board cannot allow an increase in wire width, add a Solder layer to the wire (generally, a wire of about 1mm can have an additional wire layer of about 0.6mm, of course, you can also add a 1mm Solder layer). After soldering, this 1mm wire can be considered as a 1.5mm to 2mm wire (depending on the uniformity and amount of solder during soldering), as shown in the figure below:

Methods like these are not unfamiliar to friends engaged in small household appliance PCB layout. Therefore, if the soldering amount is uniform enough and there is enough solder, this 1mm wire can be considered as more than just a 2mm wire. And this is particularly important in single-sided high current boards.

The method of handling around the solder pad in the figure also increases the uniformity of the wire and solder pad current carrying capacity, which is particularly important in boards with large current and thick pins (pins larger than 1.2 and solder pads larger than 3). Because if the solder pad is above 3mm and the pin is above 1.2, after soldering, the current of this solder pad will increase by several tens of times. If there is a large current fluctuation during the high current moment, the current carrying capacity of the entire line will be very uneven (especially when there are many solder pads), which still easily leads to the possibility of burning the line between solder pads. The treatment in the figure can effectively disperse the uniformity of the current carrying capacity of individual solder pads and surrounding lines.

Finally, it is reiterated that the current-carrying capacity data table is only an absolute reference value. When not designing for high current, increasing the amount by 10% based on the data provided in the table can absolutely meet the design requirements. In general, for single-sided board design, with a copper thickness of 35um, it can be designed at a ratio of 1:1. That is, a current of 1A can be designed with a 1mm wire, which can meet the requirements (calculated at a temperature of 105°C).

THREE The Relationship Between Copper Foil Thickness,

Trace Width, and Current in PCB Design

The current intensity of signals. When the average current of the signal is relatively high, the current-carrying capacity of the trace width should be considered. The trace width can be referenced using the following data:

Note:

i. When using copper foil as a conductor for high currents, the current-carrying capacity of the copper foil width should be selected by reducing the values in the table by 50%.

ii. In PCB design and manufacturing, OZ (ounce) is commonly used as the unit of copper foil thickness. The definition of 1OZ copper thickness is that the weight of copper foil within an area of 1 square foot is one ounce, corresponding to a physical thickness of 35um; 2OZ copper thickness is 70um.

FOUR How to Determine the Width of High Current Traces

(b) Trace thickness 35μm (c) Trace thickness 70μm (d) Trace thickness 105μm

FIVE Using PCB temperature impedance calculation software for calculating trace

width, current, impedance, etc. - PCBTEMP

Fill in the following fields sequentially: Location (External/Internal) - whether the trace is on the surface or inside the FR-4 board, Temp (Temperature in Degree Celsius), Width (Trace Width in Mil), Thickness (Copper Thickness in Oz/Mil), then click Solve to calculate the allowable current. This method also allows you to determine the trace width based on the current requirement, which is very convenient.

As you can see, the results are similar to the first method (20 degrees Celsius, 10 mil trace width, equivalent to 0.010 inch trace width, with a copper thickness of 1 oz).

Where:

K is the correction coefficient, generally taken as 0.024 for inner layer copper and 0.048 for outer layer copper;

T is the maximum temperature rise, measured in degrees Celsius (copper's melting point is 1060°C);

A is the cross-sectional area of the copper, measured in square mil (not millimeters, note it is square mil);

I is the permissible maximum current, measured in amperes (amp).

Generally: 10 mil = 0.010 inch = 0.254 mm can carry 1A,

250 mil = 6.35 mm, can carry 8.3A.

SEVEN The calculation method provided by a netizen is as follows

Some experience about line width and copper plating for vias.

When drawing PCBs, there is a general rule of thumb: use thicker traces (such as 50 mil or more) for high-current paths and thinner traces (such as 10 mil) for low-current signals. For certain electromechanical control systems, where transient currents can exceed 100A, using thin traces will undoubtedly lead to problems.

A basic empirical value is 10A per square millimeter, meaning a trace with a cross-sectional area of 1 square millimeter can safely carry a current of 10A. If the trace width is too narrow, it may burn out when subjected to high currents. Of course, when a trace burns out due to a sudden current surge, the energy formula Q = I * I * t applies. For example, for a trace carrying 10A of current, if a spike of 100A occurs for a microsecond, a 30 mil trace can withstand it.

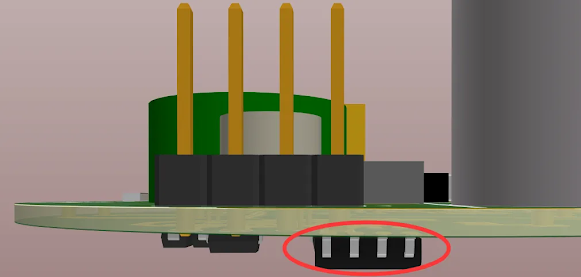

Generally, PCB design software offers several options for copper plating vias, such as right-angle spoke, 45-degree spoke, and direct plating. What are their differences? Novices often don't pay much attention and simply choose one for aesthetics. However, there are two main considerations: heat dissipation and current-carrying capacity.

The direct plating method provides strong current-carrying capacity for the vias, making it suitable for pins of high-power circuits. It also offers good thermal conductivity, which benefits device cooling. However, it poses a challenge for soldering personnel due to its rapid heat dissipation, often requiring larger wattage soldering irons and higher soldering temperatures, which reduces production efficiency. On the other hand, using right-angle and 45-degree spokes reduces the contact area between pins and copper foils, slowing heat dissipation and making soldering easier. Therefore, the choice of via plating method should consider both the current-carrying capacity and heat dissipation requirements. For low-power signal lines, avoid using direct plating, while for pins carrying high currents, direct plating is essential. As for choosing between right-angle and 45-degree spokes, it depends on aesthetics.

Why mention this? Because recently, I've been researching a motor driver, and the devices in its H-bridge circuit kept burning out for four or five years without any apparent reason. After much effort, I finally discovered the cause: one device's pad in the power circuit was plated with right-angle spokes (and due to poor plating, only two spokes were actually present). This greatly reduced the current-carrying capacity of the entire power circuit. Although the product had no issues during normal operation, working fine under a 10A current, when a short circuit occurred in the H-bridge, the circuit experienced a current of around 100A, causing the two spokes to burn out instantly (microseconds). Consequently, the power circuit became an open circuit, and the energy stored in the motor dissipated through any possible path, burning out the current sensing resistor and related operational amplifier components, damaging the bridge control chip, and entering the digital circuitry, resulting in severe damage to the entire device. The whole process was like using a hair to trigger a large landmine.

Why were only two spokes used for plating on the power circuit pad? Why not let the copper foil directly cover it? Because the production staff said it would be too difficult to solder that way!

Comments

Post a Comment