The technical implementation process of PCB cloning is simply scanning the circuit board to be cloned, recording detailed component positions, then removing the components to create a Bill of Materials (BOM) and arranging material procurement. The empty board is scanned into images and processed by cloning software to restore the PCB layout file. Next, the PCB file is sent to the fabrication factory for production. Once the boards are made, the purchased components are soldered onto the PCBs. Finally, the PCB undergoes testing and debugging.

The specific steps of PCB cloning are as follows:

1. Upon receiving a PCB, start by documenting all component models, parameters, and positions on paper, paying special attention to the orientation of diodes, transistors, and IC notches. It's advisable to take a couple of photos of the component positions using a digital camera. Nowadays, with increasingly advanced PCBs, some components are difficult to identify without careful attention.

2. Remove all components from the PCB, especially those on multi-layer boards, and clean the PCB thoroughly by removing any solder from the pad holes using alcohol. Then, place the PCB in a scanner, adjusting the scanner settings to slightly increase the scanning resolution for clearer images. Next, lightly sand the top and bottom layers with water sandpaper until the copper foil shines, then scan both layers separately. Ensure the PCB is placed flat inside the scanner to obtain usable scan images.

3. Adjust the contrast and brightness of the scanned images to emphasize the areas with copper foil against those without. Convert the images to black and white and check if the lines are clear. If not, repeat this step. If clear, save the images as black and white BMP files named TOP.BMP and BOT.BMP. If there are issues with the graphics, they can be patched and corrected using Photoshop.

4. Convert the two BMP files into PROTEL format files. Load both layers into PROTEL. If the positions of pads and vias on both layers mostly coincide, it indicates good progress in the previous steps. If there are discrepancies, repeat step three. Therefore, PCB cloning requires a great deal of patience, as even small issues can affect the quality and matching accuracy after cloning.

5. Convert the TOP layer BMP into a TOP.PCB file, ensuring it is converted to the SILK layer (yellow layer). Then, draw lines on the TOP layer according to the schematic obtained in step two, and place the components accordingly. Once done, delete the SILK layer. Repeat this process until all layers are drawn.

6. In PROTEL, merge the TOP.PCB and BOT.PCB files into one.

7. Print the TOP LAYER and BOTTOM LAYER onto transparent films using a laser printer (1:1 scale). Place the films onto the PCB to check for any errors. If everything is correct, you have completed the process successfully.

Cloning a PCB identical to the original is achieved, but this only marks the halfway point. Testing must be conducted to ensure the cloned board's electronic performance matches that of the original. If it does, then the task is truly accomplished.

Note: If the PCB is a multi-layer board, extra care must be taken to sand the inner layers. Additionally, repeat steps three to five of the cloning process. The naming of the graphics will differ according to the number of layers. Generally, cloning a double-sided board is much simpler than cloning a multi-layer board. Cloning a multi-layer board can easily lead to misalignment issues, so extra attention and caution are required (especially concerning the continuity and discontinuity of inner vias).

Cloning Method for Double-Sided PCB:

1. Scan the top and bottom layers of the circuit board and save two BMP images.

2. Open the cloning software Quickpcb2005, click on "File" then "Open Base Image," and open one of the scanned images. Use PAGEUP to zoom in on the screen, locate the solder pads, press PP to place a solder pad, and trace the lines by pressing PT... just like drawing for a child. Draw once in this software, then click "Save" to generate a B2P file.

3. Click on "File" then "Open Base Image" again, and open the scanned color image of the other layer.

4. Click on "File" then "Open," and open the previously saved B2P file. We will see the newly cloned board overlaid on this image - it's the same PCB board, with holes in the same positions, but with different connections. So, go to "Options" - "Layer Settings," and here, disable the display of the top layer's traces and silkscreen, leaving only the multi-layer vias visible.

5. The vias on the top layer correspond to those on the bottom layer image. Now, just like drawing in childhood, trace out the bottom layer's traces. Then, click "Save" - the B2P file now contains data for both the top and bottom layers.

6. Click on "File" then "Export to PCB File" to obtain a PCB file with data for both layers. This file can be further modified, used to generate schematics, or directly sent to a PCB fabrication factory for production.

Cloning Method for Multi-layer PCBs:

Actually, cloning a four-layer board is simply duplicating two double-sided boards, while a six-layer board involves duplicating three double-sided boards... The reason why multi-layer boards can be intimidating is because we cannot see their internal traces. How can we uncover the secrets of the inner layers of a sophisticated multi-layer board? Through layer separation.

There are many methods for layer separation, such as chemical etching and knife stripping, but they often result in over-separation and data loss. Experience tells us that sandpaper grinding is the most accurate method.

After cloning the top and bottom layers of the PCB, it's common practice to use sandpaper grinding to reveal the internal layers. Ordinary sandpaper available at hardware stores is typically used. The PCB is laid flat, and the sandpaper is pressed evenly against it, ensuring uniform grinding. If the board is small, it can also be placed flat on the sandpaper and rubbed with a finger. The key is to ensure flatness for uniform grinding.

Silkscreen and green solder mask usually come off with one rub, while copper traces and copper foil require a bit more rubbing. Generally, a Bluetooth board can be rubbed clean in a few minutes, while a memory module might take around ten minutes. Of course, exerting more force will reduce the time required, while less force will prolong it.

Grinding the board is currently the most common and economical method for layer separation. You can try it out on a piece of scrap PCB. In reality, grinding the board isn't very technically challenging; it's just a bit tedious and requires some effort. There's no need to worry about grinding through the board or wearing down your fingers.

During the PCB layout process, after the system layout is completed, it is necessary to review the PCB diagram to determine whether the system layout is reasonable and whether it can achieve optimal results.

Usually, examination can be conducted from several aspects as follows:1. Whether the system layout ensures rational or optimal routing, reliable wiring, and the reliability of circuit operation. During layout, it's necessary to have an overall understanding and plan for signal routing, as well as power and ground networks.

2. Whether the PCB dimensions match the processing drawings, meet PCB manufacturing process requirements, and include behavior markings. This aspect requires special attention as many PCB layouts and wiring designs may appear elegant and reasonable, yet overlook precise positioning of connectors, resulting in the inability of the designed circuit to interface with others.

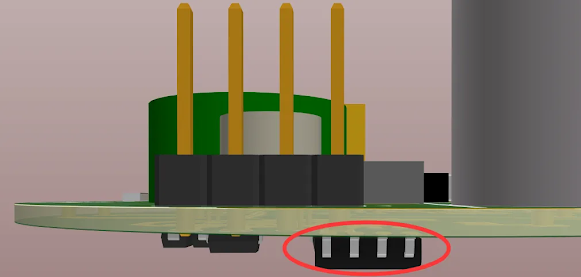

3. Whether there are conflicts in the two-dimensional and three-dimensional space occupied by components. Pay attention to the actual dimensions of components, especially their heights. For components to be soldered without layout, the height generally should not exceed 3mm.

4. Whether the component layout is orderly, compact, and complete. During component layout, consider not only the direction and type of signals and areas needing attention or protection but also the overall density of component placement, ensuring a balanced density.

5. Whether components requiring frequent replacement can be easily replaced and whether plug-in board insertion into devices is convenient. It should ensure that the replacement and insertion of components requiring frequent replacement are both convenient and reliable.

Disclaimer: The content of this article is sourced from the internet, and all rights belong to the original author. If there are any copyright issues concerning the works mentioned, please contact me for removal.

Comments

Post a Comment